Game Bub Update: Injection Molding Underway and New Manufacturing Partnership Announced

Game Bub, the open-source FPGA retro-emulation handheld, has released its February manufacturing update, highlighting significant progress in hardware production and a strategic shift in its supply chain.

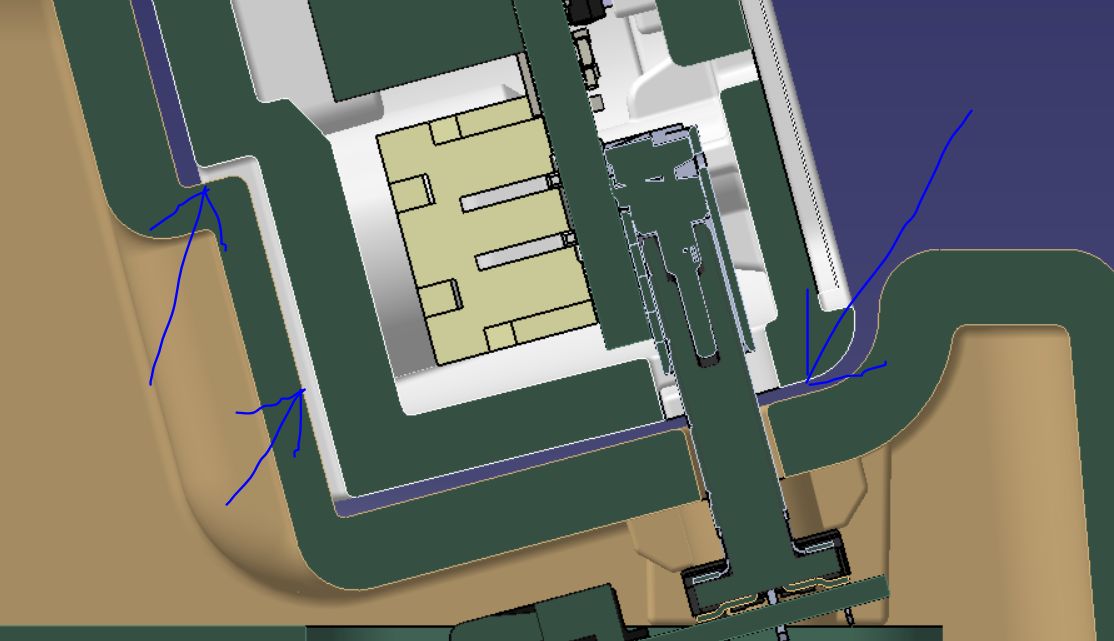

Mechanical Design and Injection Moulding

Following the finalization of mechanical designs in January, stainless steel molds for the device are officially in production. Due to the complexity of the machining process and the Lunar New Year holiday, the first sample parts are expected in late March.

A notable upgrade for backers is the production of the Game Bub Dock. While originally planned as a 3D-printed PLA component, the project’s successful funding has allowed the team to switch to injection molding for the Dock as well, providing a more premium fit and finish.

It’s noted that recent design efforts focused on internal refinements to improve durability and assembly, including:

- Adjusting wall thicknesses for structural integrity.

- Redesigning buttons for better mold ejection.

- Finalizing the handheld-to-dock USB Type-C interface.

Strategic Manufacturing Shift

In a move to streamline logistics, the project has transitioned its final assembly and packaging to Elecrow, a manufacturer based in Shenzhen, China. This change replaces the previous European-based manufacturer and is expected to reduce potential delays.

By utilizing a manufacturer located in the same region as the primary component suppliers (moulds, LCDs, and batteries), the team avoids the lengthy international shipping and customs processes previously required to move parts from China to Europe. It’s reported that they have already seen faster iteration times, completing multiple button component samples in just a few days.

LCD and Battery Samples

With the mechanical specifications set, production has also commenced on the samples for the custom laminated LCD screen and the dual-cell battery pack. Both components are slated for delivery and verification in March.

Next Steps

While waiting for physical samples, the developers are focusing on:

- Polishing the 1.0 firmware release.

- Authoring the official user guide and safety documentation.

- Preparing for mass production once samples are validated.

Community Engagement

To facilitate better communication with backers and enthusiasts, the team has launched an official Discord server. While Discord will serve as a hub for community interaction, the team confirmed that all major project milestones will continue to be posted via official Crowd Supply updates.

You can find the most recent update from the project here.